This article explores the wide-ranging applications of CNC machining across various industries. We will delve into the diverse uses of CNC machines, highlighting their pivotal role in modern manufacturing and the production of high-precision components. From aerospace to automotive and beyond, CNC technology is revolutionizing how products are made.

CNC Machine Overview

What is a CNC Machine?

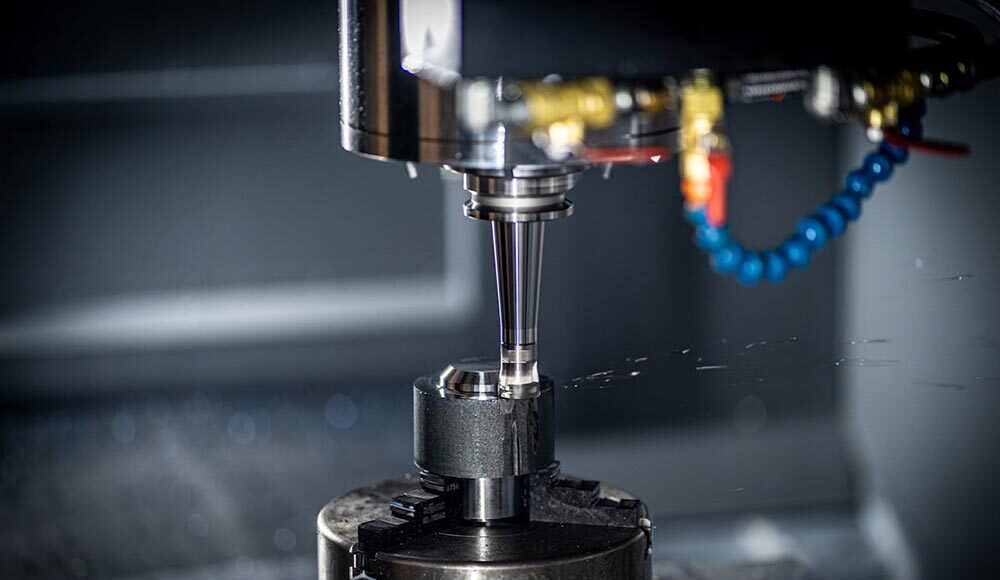

A CNC machine, short for computer numerical control machine, represents a cornerstone of modern manufacturing. It is an automated machining process that relies on CNC programming to precisely control a cutting tool’s movements. This enables the creation of complex and intricate parts from a wide range of materials, including metal and plastic. The use of CNC systems ensures high precision and repeatability in the machining process, which is essential for manufacturing components with tight tolerances.

How CNC Machines Operate

CNC machines operate by interpreting digital instructions, typically in the form of G-code, to guide the cutting tool along a programmed path. This automation allows for the machining process to be highly accurate and efficient. Different types of CNC machines are used for various applications of CNC machining. For example, a CNC milling machine uses rotary cutting tools to remove material, while a CNC lathe rotates the work piece against a stationary cutting tool. CNC routers and CNC plasma cutters are commonly used for cutting sheet materials.

Importance of CNC in Modern Manufacturing

The importance of CNC in modern manufacturing cannot be overstated. CNC machining is also vital in manufacturing components used in the aerospace industry, automotive manufacturing, and the electronics industry. The applications of CNC machining extend to R&D for prototype development and mass production. With a wide range of materials able to be used for cutting, CNC machining services can engrave, drill, and shape parts with unparalleled accuracy and speed. Modern manufacturing heavily relies on CNC for its automation and ability to produce parts with high precision and repeatability. Various industries use CNC for its many benefits.

Applications of CNC Machining

CNC Machine Applications in Various Industries

The applications of CNC machining span various industries, showcasing the CNC machine’s versatility and adaptability. CNC machining is also used extensively in the aerospace industry, where high precision components are crucial for aircraft performance and safety. The automotive manufacturing sector relies on CNC for producing engine parts, transmission components, and custom body panels. Other CNC machine applications include metal fabrication, plastic part production, and even creating intricate designs in the signage industry.

Precision Machining and Prototyping

Precision is paramount in R&D and prototype development, making CNC machining an invaluable asset. The use of CNC allows engineers and designers to rapidly create and refine prototype parts with exacting specifications. This accelerates the design process, enabling faster iteration and improved product development cycles. Whether it’s creating functional prototype or fine-tuning the design for mass production, CNC machining ensures the required accuracy and repeatability.

CNC Machining Processes in Metal Fabrication

CNC machining processes are essential for metal fabrication. CNC machines are used for cutting, shaping, and finishing metal parts with exceptional precision. Applications include creating complex geometries, intricate patterns, and tight tolerances that are difficult to achieve with traditional methods. From structural components to decorative elements, the use of CNC enhances the quality, accuracy, and efficiency of metal fabrication. Furthermore, CNC drilling machines and other specialized machines can be used in metal fabrication.

CNC Milling and Its Uses

Understanding CNC Milling Machines

A CNC milling machine is a versatile computer numerical control machine used to remove material from a workpiece to create a desired shape or design. The CNC milling machine operates by rotating a cutting tool against a stationary or moving workpiece. CNC milling is crucial for manufacturing components, especially in the semiconductor, optical communication, electronics industry, and oil and gas industry, where intricate designs and precise tolerances are required.

Common CNC Milling Applications

The common CNC applications of CNC machining include creating molds and dies, machining complex parts for the aerospace industry, and manufacturing components for medical devices. The ability to produce parts with high precision and excellent surface finishes makes CNC milling ideal for a wide range of applications. Modern manufacturing utilizes CNC milling for automation and ability to produce parts with repeatability. CNC milling is also utilized in automotive manufacturing for creating complex parts.

Benefits of CNC Milling in Production

The benefits of CNC milling in production are numerous. It offers automation, increased efficiency, and reduced labor costs. The CNC milling machine also allows for complex designs to be manufactured with greater ease and accuracy than traditional methods. The repeatability and consistency of CNC milling ensures that parts are manufactured to the exact same specifications every time. The CNC technology ensures the best outcomes when uses of CNC machines are employed.

Common Materials Used in CNC Machining

Metals in CNC Machining

In the world of CNC machining, metal reigns supreme due to its strength and versatility. Various industries heavily depend on the precision and durability that metal components offer, making them ideal for CNC machine applications. From aluminum and steel to titanium and copper, the use of CNC allows for intricate designs and tight tolerances in the aerospace industry, automotive manufacturing, and more. The machining process with metal benefits from the repeatability and automation that CNC machining ensures for consistent results.

Plastics and Composites

While metal often takes center stage, plastic and composites also play a significant role in CNC machining. These materials offer lightweight alternatives, corrosion resistance, and electrical insulation properties. CNC routers and CNC plasma cutters are excellent for cutting and shaping plastic sheets, while CNC machining can produce intricate 3D prototype parts from polymers. The use of CNC allows for precise control over material removal, ensuring high-quality results in the electronics industry and beyond.

Wood and Other Materials

Beyond metal and plastic, CNC machines demonstrate their versatility by working with wood and other materials. Woodworking benefits greatly from CNC routers, enabling the creation of intricate carvings, furniture components, and architectural details. Even softer materials like foam and wax can be machined with precision for prototype modeling and mold making. The ability to adapt to diverse materials expands the applications of CNC machining across various industries, showcasing its adaptability and innovative potential.

Future Trends in CNC Machining

Advancements in CNC Technology

The future of CNC technology is marked by relentless innovation. Expect to see more sophisticated CNC programming and control systems, enabling even greater precision and efficiency. The integration of artificial intelligence (AI) and machine learning (ML) will optimize cutting paths, predict tool wear, and automate process adjustments. These advancements will enhance the automation and repeatability of CNC machining, making it indispensable in modern manufacturing processes.

Smart Manufacturing and CNC Machines

Smart manufacturing, also known as Industry 4.0, is revolutionizing how CNC machines operate. Connected CNC machining systems can communicate with each other, share data, and adapt to changing conditions in real-time. This interconnectedness allows for predictive maintenance, optimized scheduling, and improved overall efficiency. Smart CNC technology allows for greater visibility and control over the entire manufacturing process, leading to increased productivity and reduced costs.

The Role of CNC in Sustainable Manufacturing

As sustainability gains prominence, CNC machining is also playing a crucial role in eco-friendly manufacturing processes. CNC machines can optimize material usage, minimize waste, and reduce energy consumption. The use of CNC also enables the production of lightweight components, contributing to fuel efficiency in automotive and aerospace industry. By embracing sustainable practices, CNC machining can contribute to a more environmentally responsible future for manufacturing components and various industries.

##